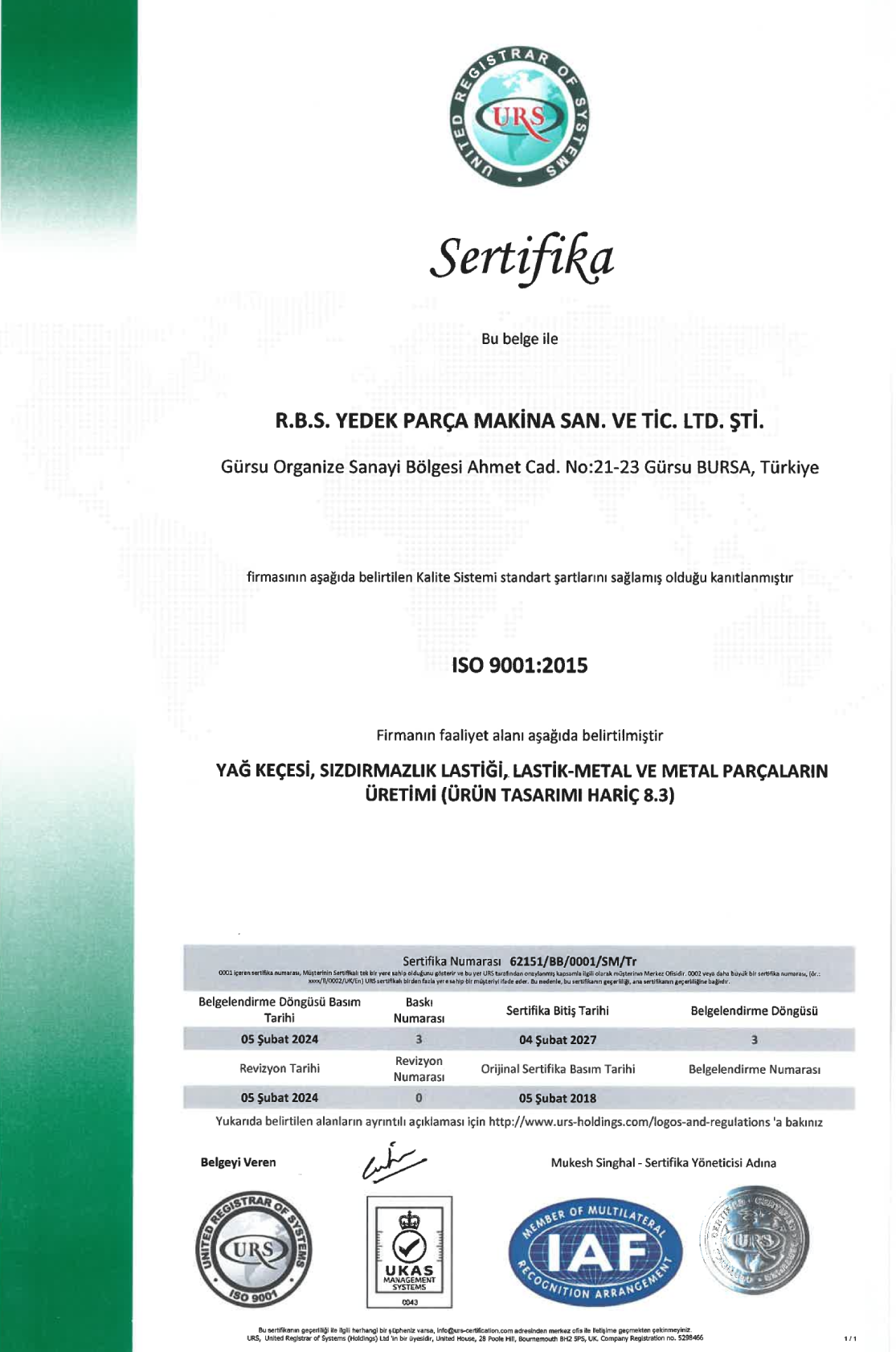

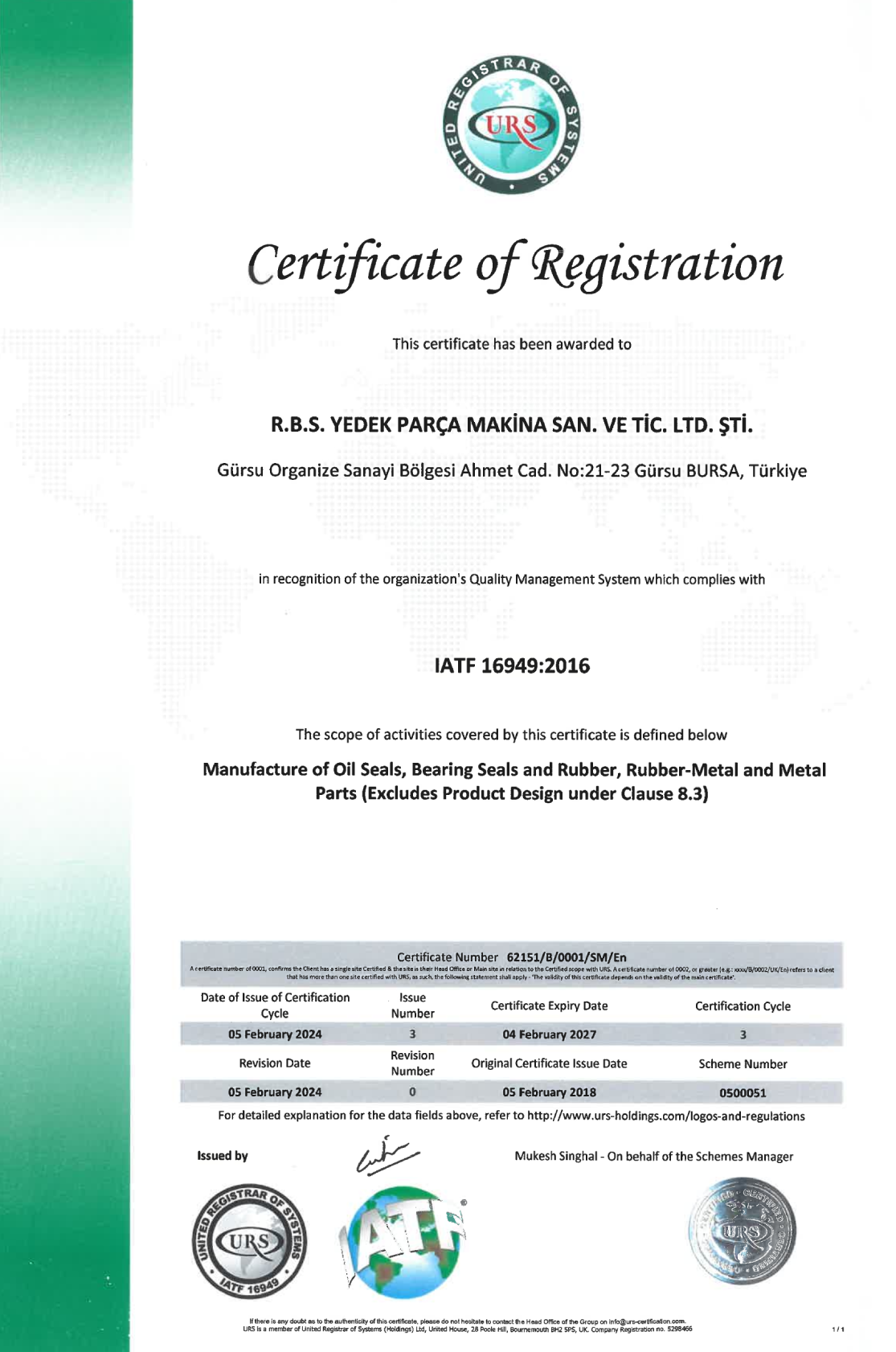

About R.B.S. Spare Parts And Machinery

R.B.S. was established in 1987 and moved to its current facility in 1993, which holds 8500 m² of closed area.

R.B.S. primarily serves to the bearing and the automotive industry. EU countries, Russia and USA are our reference exporting countries.

There are currently 195 employees.

8500 m² of

Closed area.